Digital Elmendorf Tearing Tester YG033C: Testing Fabric Strength the Smart Way

Ever wonder how companies make sure your jeans won’t rip the first time you bend over? Or how they know that expensive upholstery fabric will actually last? Well, they use something called tearing tests, and it’s way more important than most people realize. Before any fabric makes it to stores, it gets put through some serious testing to see how strong it really is. One of the best tools for this job is the Digital Elmendorf Tearing Tester YG033C, and trust me, it’s a game-changer for anyone who needs to test fabric strength.

What’s an Elmendorf Tearing Tester Anyway

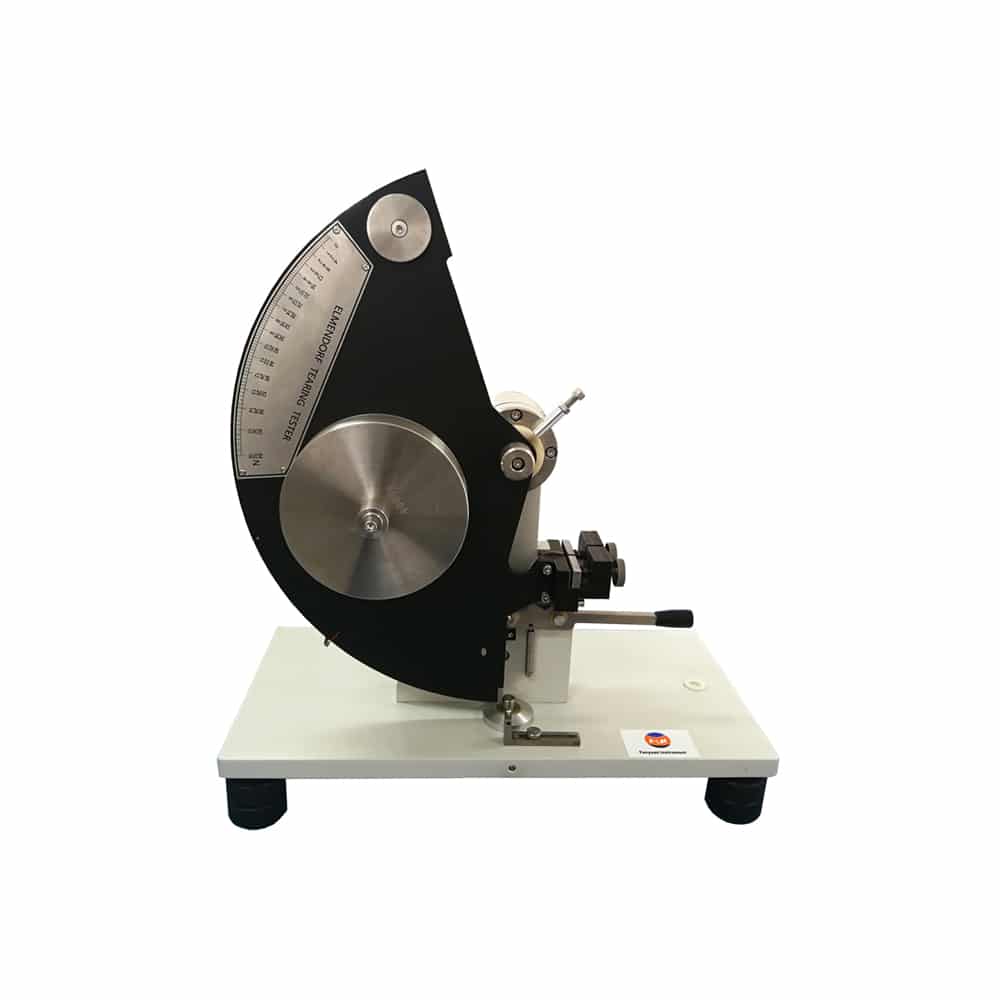

An Elmendorf tearing tester is basically a machine that figures out how much force it takes to rip fabric once you make a small cut in it. Think of it like this – you know how once you get a small tear in a shirt, it’s way easier to rip it further? This machine measures exactly how much force that takes.

It’s not just for clothes either. They use these things to test paper, filters, medical fabrics, even those heavy tarps you see covering trucks. Basically, if it’s a sheet of material and people need to know how strong it is, this machine can test it.

Why the Digital YG033C is Actually Pretty Cool

The YG033C is the digital version, and it’s got some serious advantages over the old manual ones. Here’s what makes it special.

First off, it’s got a digital display that shows you exactly what’s happening in real time. No more squinting at tiny needles on dials or trying to read measurements that might be off. The computer does all the math for you and shows you the results clearly.

It’s also way more sensitive than the old manual ones. It can pick up tiny differences in fabric strength that you might miss with manual testing. Plus, it stores all your data digitally, so you can track results over time, print reports, and send data to other people without having to write everything down by hand.

For labs that do a lot of testing, this thing is a lifesaver. No more human error from misreading gauges, no more lost paperwork, and way faster testing overall.

The Manual Versions Still Have Their Place

Now, I don’t think the manual versions are useless. The YG033A and YG033B models are still really popular, and for good reason.

They’re way cheaper than the digital version, which matters a lot if you’re running a small lab or just starting out. They’ve been around forever and people trust them – there’s something to be said for a machine that’s been doing the same job reliably for decades.

The best part about manual testers is they don’t need electricity. Sounds basic, but if you’re working somewhere with power issues or you need to do testing in the field, these manual ones just keep working no matter what.

My friend who runs a small textile testing lab swears by his manual tester. He says it’s been going strong for fifteen years and has never let him down.

Digital vs Manual – Which One Should You Get

This really depends on what you need and what you can afford.

If you’re doing a lot of testing and need super accurate results, the digital YG033C is worth the extra money. It’s faster, more accurate, and way easier to use. Plus, if you need to keep detailed records or generate reports for customers, the digital data storage is huge.

But if you’re just doing occasional testing or you’re on a tight budget, the manual versions work great. They’ll give you reliable results, they’re simple to maintain, and they cost a lot less upfront.

I’ve seen big companies use both – digital for their main production line testing and manual ones as backups or for special projects.

Who Actually Uses These Things

These testers are used in way more places than you might think.

Clothing companies use them to make sure your shirts and pants won’t fall apart after a few washes. Furniture companies test upholstery fabrics to make sure they can handle daily use. Paper companies test everything from notebook paper to cardboard boxes.

Even medical companies use them to test things like surgical gowns and face masks. If it’s made of fabric or paper and needs to be strong, somebody’s probably testing it with one of these machines.

Industrial companies test heavy-duty stuff too – tarps, sails, conveyor belts, all kinds of technical fabrics that need to be incredibly strong.

Real Example of How This Stuff Works

I heard about this fabric company in Asia that switched from manual testers to the digital YG033C. They said it cut their testing time by 20% and made their results way more consistent.

That might not sound like a big deal, but when you’re testing hundreds of fabric samples a day, that time savings adds up fast. Plus, they were able to meet international export standards more easily because their data was so much more accurate and detailed.

The company said it paid for itself pretty quickly just from the time savings alone, not to mention avoiding the cost of having defective products returned from customers.

How to Pick the Right One for You

Think about what you actually need before you buy anything.

If you’re running a big operation, doing lots of tests every day, and need detailed records, go with the digital YG033C. Yeah, it costs more upfront, but it’ll save you time and hassle in the long run.

If you’re a smaller operation, don’t do tons of testing, or you’re watching your budget carefully, the manual YG033A or YG033B will do the job just fine. They’re reliable, proven, and way less expensive.

Either way, you’re getting a machine that’s been trusted by the textile industry for years.

The Bottom Line on Fabric Testing

Here’s the thing – whether you make clothes, furniture, paper products, or any kind of fabric, you need to know how strong your materials are. Customers expect things to last, and if your products fall apart, they’re not coming back.

The Elmendorf tearing tester, whether it’s the fancy digital YG033C or the reliable manual versions, gives you the data you need to make sure your products are actually as strong as they should be.

It’s one of those investments that might not seem exciting, but it protects your reputation and saves you money in the long run. Better to find out your fabric is weak in the lab than have customers complaining about torn products.

If you’re in the business of making anything with fabric or paper, these testers aren’t just nice to have – they’re pretty much essential for staying competitive and keeping customers happy.